Ahịrị mmepụta kwa afọ nke 20,000 tọn fatịlaịza ngwakọta bụ ngwakọta nke akụrụngwa dị elu.Ọnụ ego mmepụta dị ala na nrụpụta mmepụta dị elu.Enwere ike iji ahịrị mmepụta fatịlaịza jikọtara ọnụ maka granulation nke akụrụngwa dị iche iche mejupụtara.N'ikpeazụ, a pụrụ ịkwadebe fatịlaịza na-agbakọta ọnụ na usoro dị iche iche dabere na mkpa n'ezie, mejupụta nri nke ihe ọkụkụ chọrọ nke ọma, ma dozie esemokwu dị n'etiti ọchịchọ ihe ọkụkụ na oke ala.

Ahịrị mmepụta fatịlaịza mejupụtara nwere ike imepụta fatịlaịza ogige dị elu, ọkara na nke dị ala maka ihe ọkụkụ dị iche iche.Usoro mmepụta adịghị mkpa ka akọrọ, na obere ego na obere ike oriri.

Enwere ike ịhazi igwe na-emepụta ahịrị fatịlaịza mejupụtara ka ọ bụrụ ụdị na nha dị iche iche iji piakọta ma mepụta irighiri ihe dị iche iche.

N'ikwu okwu n'ozuzu, fatịlaịza ngwakọta nwere ma ọ dịkarịa ala abụọ ma ọ bụ atọ nri (nitrogen, phosphorus, potassium).O nwere njiri mara nnukwu ihe oriri na mmetụta ole na ole.Ngwakọta fatịlaịza na-ekere òkè dị mkpa n'ịgbakọta fatịlaịza kwesịrị ekwesị.Ọ nwere ike ọ bụghị naanị melite fatịlaịza arụmọrụ, ma na-akwalite mụ na elu mkpụrụ nke kụrụ.

Dị ka a ọkachamara emeputa nke fatịlaịza mmepụta akara akụrụngwa, anyị na-enye ndị ahịa na mmepụta akụrụngwa na kasị adabara ngwọta maka dị iche iche mmepụta ike mkpa dị ka 10,000 tọn kwa afọ ka 200,000 tọn kwa afọ.

Akụrụngwa maka mmepụta fatịlaịza ngwakọta gụnyere urea, ammonium chloride, ammonium sulfate, mmiri mmiri amonia, ammonium monophosphate, diammonium phosphate, potassium chloride, potassium sulfate, gụnyere ụfọdụ ụrọ na ihe ndị ọzọ.

1) Nitrogen fatịlaịza: ammonium chloride, ammonium sulfate, ammonium thio, urea, calcium nitrate, wdg.

2) Potassium fatịlaịza: potassium sulfate, ahịhịa na uyi, wdg.

3) Fatịlaịza phosphorus: calcium perphosphate, calcium perphosphate dị arọ, calcium magnesium na phosphate fatịlaịza, phosphate ore ntụ ntụ, wdg.

1.Composite fatịlaịza mmepụta akara nwere àgwà nke obere ike oriri, nnukwu mmepụta ikike na ezigbo uru akụ na ụba.

2. The mmepụta akara nakweere akọrọ granulation, na-ewepụ ihicha usoro jụrụ na ukwuu ibelata ọnụ ahịa ntinye nke akụrụngwa.

3. Usoro mmepụta fatịlaịza na-emepụta ihe bụ kọmpat na ezi uche, na-ekpuchi obere mpaghara.

4. N'ime usoro mmepụta ihe, enwere obere ike oriri na ọ dịghị ihe mkpofu atọ.Usoro mmepụta fatịlaịza mejupụtara nwere arụmọrụ kwụsiri ike, ịdị mma a pụrụ ịdabere na ya na ogologo ndụ ọrụ.

5. Enwere ike iji eriri mmepụta fatịlaịza na-emepụta ihe na-emepụta ihe dị iche iche fatịlaịza.Na ọnụ ọgụgụ granulation dị elu zuru oke.

6. Ngwakọta fatịlaịza na-emepụta ihe nwere ike ịmepụta fatịlaịza na-emepụta ihe dị iche iche iji gboo mkpa nke ndị ahịa dị iche iche.

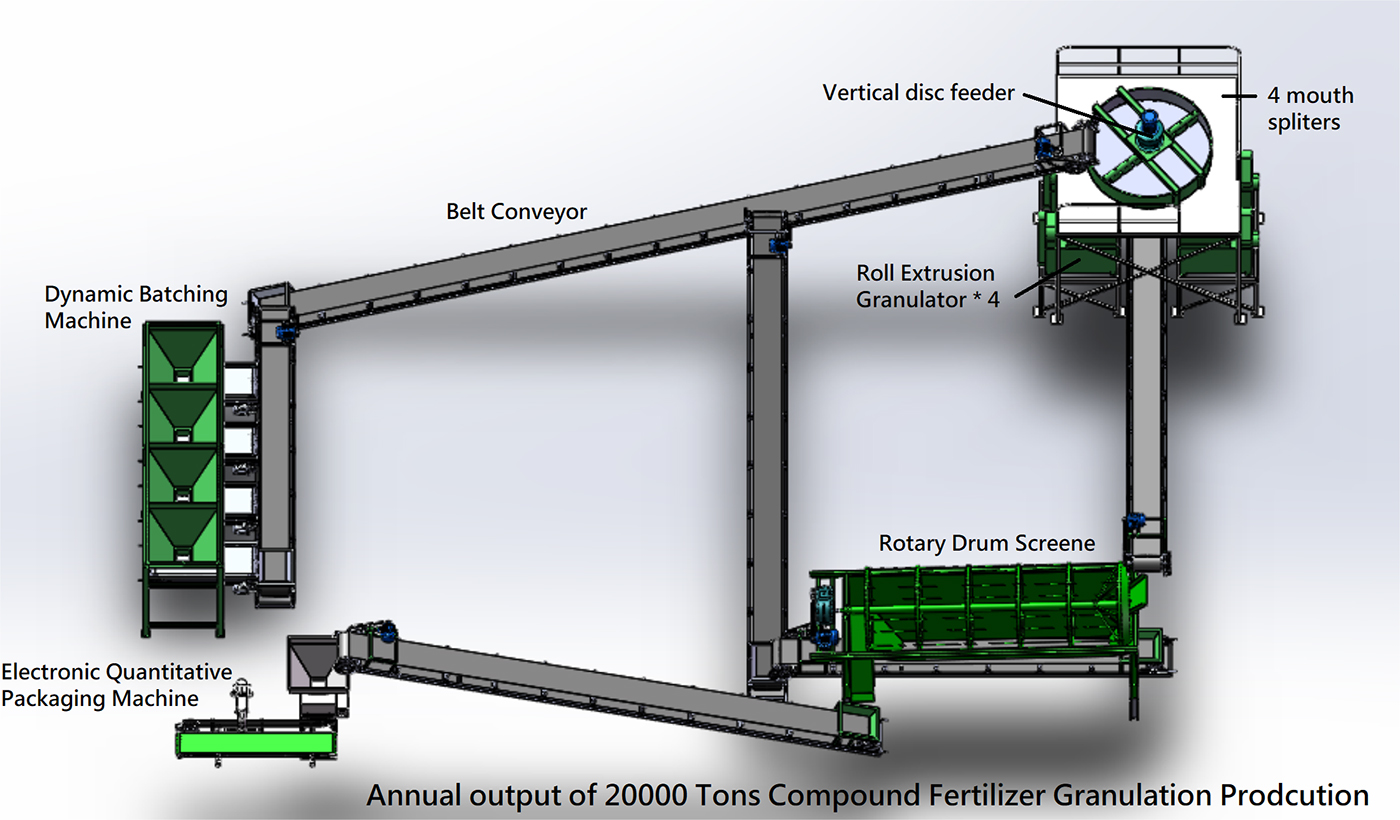

N'ikwu okwu n'ozuzu, ahịrị mmepụta fatịlaịza mejupụtara mejupụtara akụkụ ndị a: usoro ịgwakọta, usoro granulation, usoro ikpochapu, usoro nyocha, usoro mkpuchi na usoro nkwakọ ngwaahịa.

1. Igwe batching dị ike:

Enwere ike ime ihe karịrị ihe atọ.Igwe batching nwere ihe karịrị silos atọ, ma nwee ike ịbawanye ma belata silo dị ka ihe ndị ahịa chọrọ.N'ebe ọpụpụ nke silo nke ọ bụla, e nwere ọnụ ụzọ eletrọnịkị pneumatic.N'okpuru silo, a na-akpọ ya hopper, nke pụtara na ala nke hopper bụ eriri eriri.A na-ekwu na a na-ekokwasị hopper na eriri belt n'otu njedebe nke eriri nnyefe, akụkụ nke ọzọ nke lever na-ejikọta na ihe mmetụta erughị ala, na ihe mmetụta na ihe nchịkwa pneumatic na-ejikọta na kọmputa.Igwe a na-anabata nchikota nke igwe eletrọnịkị, nke onye na-ahụ maka batching na-achịkwa ya na-akpaghị aka, a na-emechakwa nha nha nke ihe ọ bụla.Ọ nwere uru nke usoro dị mfe, ihe dị elu nke ọma, ọrụ dị mfe na iji a pụrụ ịdabere na ya.

2. Igwe nhịahụ kwụ ọtọ:

Gwakọta ihe ngwakọta dị iche iche n'otu akụkụ ma tinye ha n'ime igwe nhịahụ kwụ ọtọ.A ga-egwepịa ihe ndị ahụ n'ime obere ihe iji gboo mkpa nke usoro granulation na-esote.

3. Ihe nri diski kwụ ọtọ:

Mgbe e gwepịasịrị ihe ndị ahụ, a na-eziga ya na onye na-eri nri Vertical disc feeder, a na-agwakọta ihe ndị ahụ ma mee ka ọ dị nro na mixer.Ihe mkpuchi dị n'ime nke igwekota bụ polypropylene ma ọ bụ efere igwe anaghị agba nchara.Ngwa ndị dị otú ahụ nke nwere nnukwu corrosion na viscosity adịghị mfe ịrapara na ya.Ngwakọta agwakọta ga-abanye na granulator drum.

4. Roll Extrusion Granulator:

Ịnabata nkà na ụzụ extrusion akọrọ, a na-ahapụ usoro ihicha.Ọ na-adabere na nrụgide mpụga, nke mere na a na-amanye ihe ahụ ka ejikọta ya n'ime iberibe site na nkwụsị nke abụọ ntụgharị.Ezigbo njupụta nke ihe nwere ike ịbawanye site na 1.5-3 ugboro, si otú ahụ rute ụfọdụ ọkọlọtọ ike.Karịsịa kwesịrị ekwesị maka ebe ịbawanye ibu ngwaahịa tojupụtara.Enwere ike imezi arụmọrụ na-arụ ọrụ na nhazi dịgasị iche iche site na nrụgide mmiri mmiri.Akụrụngwa abụghị naanị sayensị na ezi uche na nhazi, kamakwa ọ nwere obere ego, mmetụta ngwa ngwa na ezigbo uru akụ na ụba.

5. Rotary Drum Screene:

A na-ejikarị ya kewaa ngwaahịa emechara na ihe ejigharịgharị.Mgbe sieving, ruru eru ahụ na-nri n'ime wrapper igwe, na-erughị eru irighiri na-nri n'ime vetikal yinye crusher na-eme ka granulated ọzọ, si otú ịghọta ngwaahịa nhazi ọkwa na edo classification nke okokụre ngwaahịa.Igwe ahụ na-ejikọta ihuenyo jikọtara ọnụ maka nlekọta dị mfe na ngbanwe.Ọdịdị ya dị mfe na iberibe.Ịrụ ọrụ dị mma ma kwụsie ike bụ akụrụngwa dị mkpa na mmepụta fatịlaịza.

6. Igwe ngwungwu ọnụọgụ eletrọnịkị:

Mgbe enyochachara ihe ndị ahụ, a na-eji igwe nkwakọba chịkọta ha.Igwe nkwakọ ngwaahịa nwere oke akpaaka, na-ejikọta nha, suture, nkwakọ ngwaahịa na njem njem, nke na-achọpụta ngwugwu ọnụọgụ ngwa ngwa ma na-eme ka usoro nkwakọ ngwaahịa dịkwuo mma na nke ziri ezi.

7. ebufe eriri:

Onye na-ebugharị na-arụ ọrụ dị mkpa na usoro mmepụta, n'ihi na ọ na-ejikọta akụkụ dị iche iche nke ahịrị mmepụta dum.N'ahịrị mmepụta fatịlaịza a, anyị na-ahọrọ ịnye gị eriri eriri.E jiri ya tụnyere ụdị ndị ọzọ na-ebufe, ndị na-ebu belt nwere nnukwu mkpuchi, na-eme ka usoro mmepụta gị dịkwuo mma na nke akụ na ụba.