Ahịrị mmepụta nke 30,000 tọn fatịlaịza kwa afọ bụ ngwakọta nke akụrụngwa dị elu.Ọnụ ego mmepụta dị ala na nrụpụta mmepụta dị elu.Enwere ike iji ahịrị mmepụta fatịlaịza jikọtara ọnụ maka granulation nke akụrụngwa dị iche iche mejupụtara.N'ikpeazụ, a pụrụ ịkwadebe fatịlaịza na-agbakọta ọnụ na usoro dị iche iche dabere na mkpa n'ezie, mejupụta nri nke ihe ọkụkụ chọrọ nke ọma, ma dozie esemokwu dị n'etiti ọchịchọ ihe ọkụkụ na oke ala.

N'ime afọ ndị na-adịbeghị anya, steeti ahụ ewepụtala ma wepụta usoro iwu dị mma iji kwado mmepe nke ụlọ ọrụ fatịlaịza organic.Ka ọchịchọ nke nri organic ka ukwuu, otú ahụ ka a na-achọwanye ya.Ịbawanye ngwa nke fatịlaịza organic nwere ike ọ bụghị naanị ibelata ojiji nke fatịlaịza kemịkalụ, kamakwa melite ogo ihe ọkụkụ na asọmpi ahịa, ọ dịkwa oke mkpa maka igbochi na njikwa mmetọ nke ọrụ ugbo na-enweghị isi na nkwalite ọkọnọ nke ugbo- n'akụkụ structural mgbanwe.N'oge a, ụlọ ọrụ aquaculture aghọwo ihe na-emekarị iji mepụta fatịlaịza organic site na excreta, ọ bụghị nanị na-achọ atumatu nchedo gburugburu ebe obibi, kamakwa na-achọ uru ọhụrụ maka mmepe na-adigide n'ọdịnihu.

Ikike imepụta obere ahịrị imepụta fatịlaịza organic dị iche site na kilogram 500 ruo 1 ton kwa elekere.

Akụrụngwa maka mmepụta fatịlaịza ngwakọta gụnyere urea, ammonium chloride, ammonium sulfate, mmiri mmiri amonia, ammonium monophosphate, diammonium phosphate, potassium chloride, potassium sulfate, gụnyere ụfọdụ ụrọ na ihe ndị ọzọ.

1) Nitrogen fatịlaịza: ammonium chloride, ammonium sulfate, ammonium thio, urea, calcium nitrate, wdg.

2) Potassium fatịlaịza: potassium sulfate, ahịhịa na uyi, wdg.

3) Fatịlaịza phosphorus: calcium perphosphate, calcium perphosphate dị arọ, calcium magnesium na phosphate fatịlaịza, phosphate ore ntụ ntụ, wdg.

Dị ka a ọkachamara emeputa nke fatịlaịza mmepụta akara akụrụngwa, anyị na-enye ndị ahịa na mmepụta akụrụngwa na kasị adabara ngwọta maka dị iche iche mmepụta ike mkpa dị ka 10,000 tọn kwa afọ ka 200,000 tọn kwa afọ.

1. The akụrụngwa bụ n'ọtụtụ ebe mgbanwe na adabara granulation nke compound fatịlaịza, ọgwụ, chemical ụlọ ọrụ, ndepụta na ndị ọzọ akụrụngwa, na ngwaahịa granulation ọnụego bụ elu.

2. Ihe ize ndụ mmepụta nwere ike ịmepụta mkpokọta dị iche iche, gụnyere fatịlaịza organic, fatịlaịza inorganic, fatịlaịza ndu, fatịlaịza magnetik, wdg) fatịlaịza ngwakọta.

3. Ọnụ ala dị ala, ọrụ magburu onwe ya.Ụlọ ọrụ anyị na-arụpụta ma na-ere n'onwe ya dị ka onye na-ere ahịa kpọmkwem iji nye uru ndị ahịa kachasị na ọnụahịa kacha mma.Na mgbakwunye, ọ bụrụ na ndị ahịa nwere nsogbu teknụzụ ma ọ bụ ajụjụ mgbakọ, ha nwekwara ike ịgwa anyị okwu n'oge.

4. Ngwakọta fatịlaịza nke a na-emepụta n'ahịrị mmepụta a nwere obere mmiri absorption olu, dị mfe ịchekwa, ọ dịkwa mma maka ngwa mechanized.

5. The dum compound fatịlaịza mmepụta akara chịkọbara ọtụtụ afọ nke oru ahụmahụ na mmepụta ikike.Nke a bụ eriri mmepụta fatịlaịza na-arụ ọrụ nke ọma na nke dị ala nke emepụtarala, gbanwee ma hazie ya, na-edozi nsogbu nke arụmọrụ dị ala na ọnụ ahịa dị elu n'ụlọ na mba ọzọ.

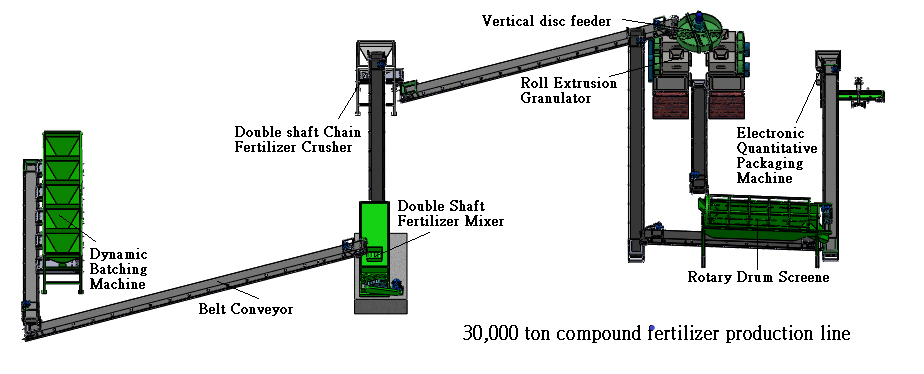

Usoro eruba nke compound fatịlaịza mmepụta akara nwere ike na-emekarị na-ekewa n'ime: raw material Efrata, Ịgwakọta, granulation, ihicha, jụrụ, urughuru classification, okokụre mkpuchi, na ikpeazụ okokụre nkwakọ.

1. Ngwa ngwa ngwa:

Dabere na ọchịchọ ahịa na nsonaazụ mkpebi ala mpaghara, urea, ammonium nitrate, ammonium chloride, ammonium thiophosphate, ammonium phosphate, diammonium phosphate, calcium siri ike, potassium chloride (potassium sulfate) na akụrụngwa ndị ọzọ na-ekesa n'otu akụkụ.A na-eji ihe mgbakwunye na ihe nchọta mee ihe dị ka ihe eji eme ihe n'otu akụkụ site na eriri eriri.Dị ka usoro nhazi ahụ si dị, a na-esi n'úkwù na-asọba ngwa ngwa ngwa ngwa, usoro a na-akpọ premixes.Ọ na-achọpụta izi ezi nke nhazi ahụ ma chọpụta ihe ndị na-arụ ọrụ nke ọma na-aga n'ihu ma na-arụ ọrụ nke ọma.

2. Ngwakọta agwakọta:

Ngwakọta kwụ ọtọ bụ akụkụ dị mkpa nke mmepụta.Ọ na-enyere akụrụngwa aka ịgwakọta nke ọma ọzọ ma tọọ ntọala maka fatịlaịza granular dị elu na nke dị elu.Ana m emepụta igwekota kwụ ọtọ na otu-axis na igwekota okpukpu abụọ ka ịhọrọ site na ya.

3. granulation:

Granulation bụ akụkụ bụ isi nke ahịrị mmepụta fatịlaịza.Nhọrọ nke granulator dị ezigbo mkpa.Ụlọ ọrụ anyị na-emepụta granulator diski, drum granulator, roller extruder ma ọ bụ granulator fatịlaịza ọhụrụ.N'ahịrị mmepụta fatịlaịza mejupụtara, anyị na-ahọrọ granulator rotary drum.Mgbe agwakọtachara ihe ahụ nke ọma, a na-ebuga eriri eriri na igwe granulation nke rotary iji mechaa granulation.

4.Nyocha:

Mgbe ọ dị jụụ, ihe ndị na-eme ntụ ntụ na-anọgide na ngwaahịa emechara.Enwere ike iji sieve anyị kpuchie ihe niile dị mma ma buru ibu.A na-ebufe ezigbo ntụ ntụ a na-ekpuchi ekpuchi site na eriri belt gaa na blender iji kpalie akụrụngwa ọzọ iji mee granulation;mgbe nnukwu ahụ na-adịghị ezute urughuru ọkọlọtọ mkpa ka a ga-ebuga ga-echi ọnụ n'ala site a yinye crusher tupu granulation.A ga-ebuga ngwaahịa emechara na igwe mkpuchi fatịlaịza.Nke a na-etolite usoro mmepụta ihe zuru oke.

5.Nkwakọ ngwaahịa:

Usoro a na-ewere igwe nkwakọ ngwaahịa akpaka.Igwe a na-eji igwe na-atụ ihe na-akpaghị aka, usoro ihe na-ebufe, igwe mkpuchi, wdg Ị nwekwara ike hazie hoppers dịka ihe ndị ahịa chọrọ.Ọ nwere ike na-aghọta na quantitative nkwakọ nke nnukwu ihe dị ka organic fatịlaịza na compound fatịlaịza, na e ọtụtụ-eji na nri nhazi ụlọ ọrụ na ulo oru mmepụta ahịrị.