Anyị nwere ahụmahụ zuru oke na ahịrị mmepụta granulation extrusion enweghị nkụ.Ọ bụghị nanị na anyị na-elekwasị anya na usoro ọ bụla njikọ na mmepụta usoro, kamakwa mgbe ịghọta usoro nkọwa nke ọ bụla dum mmepụta akara na were were nweta interlinking.Usoro mmepụta zuru oke bụ otu n'ime uru dị mkpa nke imekọ ihe ọnụ gị na Yizheng Heavy Industries.Anyị na-enye ahaziri mmepụta ahịrị ngwọta dị ka n'ezie mkpa nke ndị ahịa.

Ọ dịghị ihicha extrusion granulation mmepụta akara nwere ike ịmepụta elu, ọkara na ala ịta onyinye fatịlaịza dị iche iche kụrụ.Usoro mmepụta adịghị mkpa ka akọrọ, na obere ego na obere ike oriri.

Enwere ike ịmebe roller na-enweghị ihicha extruding granulation n'ime ihe dị iche iche nke ụdị na nha dị iche iche ma nwee ike ịmepụta ya iji mepụta nha dị iche iche.

Ngwakọta fatịlaịza nwere njiri mara granulation otu, agba na-egbuke egbuke, ịdị mma kwụsiri ike, yana mgbasa dị mfe nke ihe ọkụkụ ga-etinye obi gị dum.Karịsịa, ọ dịtụ mma maka mkpụrụ na-eto fatịlaịza.Kwesịrị ekwesị maka ụdị ala na ọka wit niile, ọka, egusi na mkpụrụ osisi, ahụekere, akwụkwọ nri, agwa, ifuru, osisi mkpụrụ osisi na ihe ọkụkụ ndị ọzọ.Ọ dabara maka fatịlaịza isi, fatịlaịza, ịchụ fatịlaịza, fatịlaịza na ogbugba mmiri n'ubi.

Akụrụngwa maka mmepụta fatịlaịza na-agụnye urea, ammonium chloride, ammonium sulfate, mmiri mmiri amonia, ammonium monophosphate, diammonium phosphate, potassium chloride, potassium sulfate, gụnyere ụfọdụ ụrọ na ihe ndị ọzọ.A na-agbakwunye ihe organic dị iche iche dịka mkpa ala si dị:

1. Nri anụ: ọkụkọ, nsị ezì, nsị atụrụ, egwu ehi, nsị ịnyịnya, nri oke bekee, wdg.

2. Ihe mkpofu ụlọ ọrụ: mkpụrụ vaịn, slag mmanya, ihe fọdụrụ akpu, ihe fọdụrụ na shuga, mkpofu biogas, ihe fọdụrụ ajị, wdg.

3. Ihe mkpofu ugbo: ahihia ihe ubi, ntụ ọka soybean, ntụ ọka owu, wdg.

4. Ihe mkpofu ụlọ: ihe mkpofu kichin

5. Sludge: sludge obodo ukwu, mmiri mmiri, nzacha sludge, wdg.

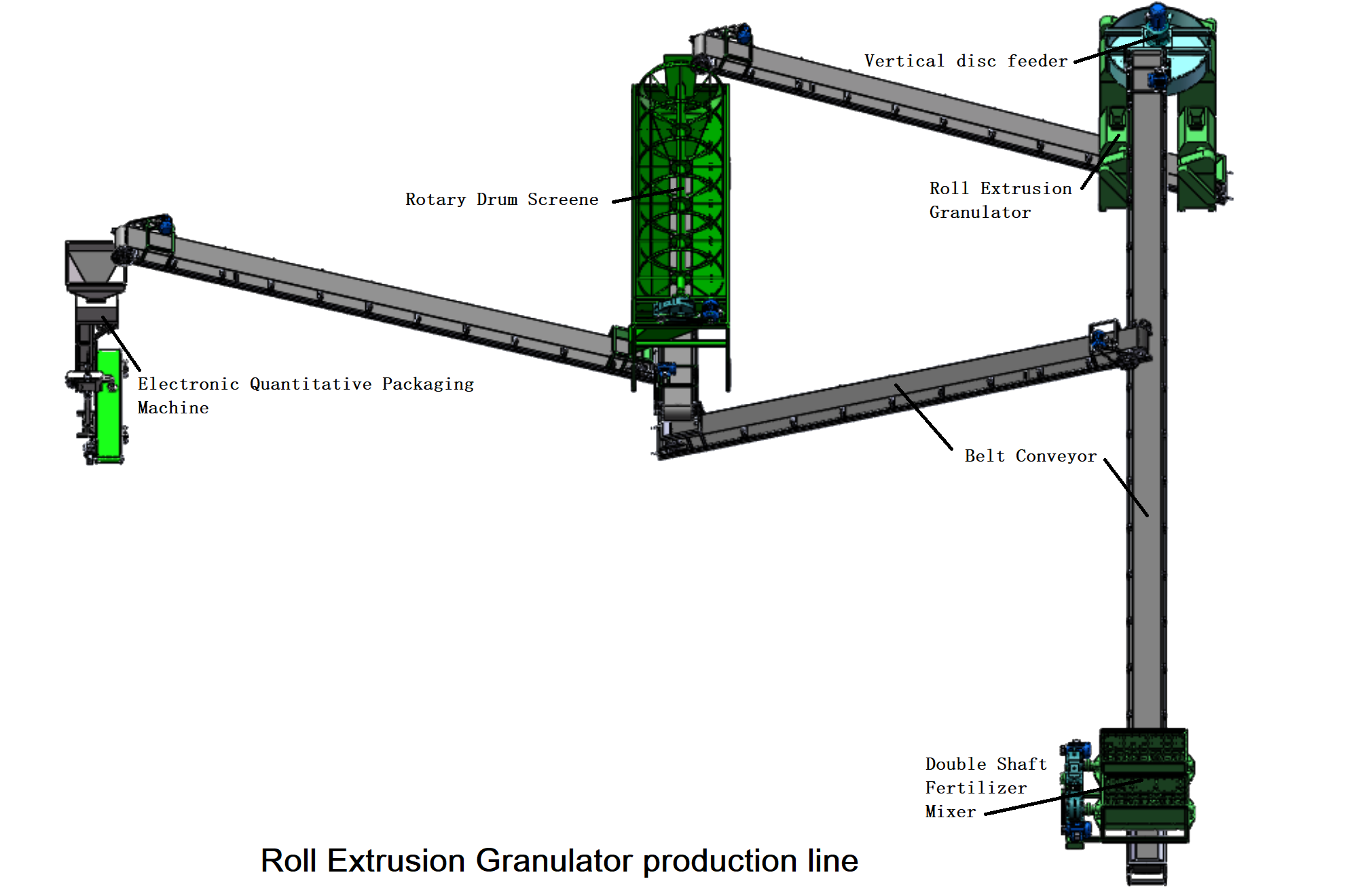

Anyị na-enye usoro mmepụta ahịrị granulation na-enweghị nkụ nke na-adịghị mkpa ka akpọnwụọ.Ngwa ahịrị na-emepụta ihe na-agụnye igwekota, onye na-enye diski, igwe na-eku ume, igwe na-eku ume, eriri eriri, igwe nkwakọ ngwaahịa akpaka na ngwa enyemaka ndị ọzọ.

Dị ka ọkachamara emeputa nke fatịlaịza mmepụta akara akụrụngwa, anyị na-enye ndị ahịa na mmepụta akụrụngwa na kasị adabara ngwọta maka dị iche iche mmepụta ike mkpa dị ka 10,000 tọn kwa afọ ka 200,000 tọn kwa afọ.

1. Mechanical mgbali granulation na-eji na-enweghị kpo oku ma ọ bụ humidifying akụrụngwa.

2. Kwesịrị ekwesị maka akụrụngwa na-emetụ ọkụ, dị ka ammonium bicarbonate

3. Ọ dịghị mkpa ikpochapụ usoro ahụ, na-eji obere ego na obere ume ike.

4. Enweghị mmiri mkpofu, ikuku gas na-ekpochapụ, enweghị mmetọ nke gburugburu ebe obibi.

5. The urughuru size nkesa bụ edo, na ọ dịghị segregation na agglomeration.

6. Nhazi kọmpat, teknụzụ dị elu, arụ ọrụ kwụsiri ike na mmezi dị mma.

7. Ọ dị mfe ịrụ ọrụ, dị mfe ịghọta njikwa akpaaka, ma melite arụmọrụ mmepụta.

8. Enwere ngwa ngwa ngwa ngwa na-enweghị ọrụ pụrụ iche chọrọ.

Ọ dịghị ihicha extrusion granulation mmepụta akara na-agụnye akpaka batcher, belt ebu, abụọ-axis blender, disc feeder, extrusion granulation igwe, roller screening igwe, okokụre ụlọ nkwakọba ihe, akpaka nkwakọ igwe, wdg.

1. Igwe eji eme ihe na-agbanwe agbanwe

Igwe ihe eji eme ihe na-akpaghị aka na-eri nri dị ka usoro usoro ọ bụla si dị, nke nwere ike mezue usoro batching na akpaghị aka na oke ziri ezi na arụmọrụ, iji hụ na fatịlaịza dị mma.Mgbe ihe ndị ahụ gasịrị, a na-ebuga ihe ahụ na blender okpukpu abụọ.

2. Ngwakọta fatịlaịza okpukpu abụọ

Ngwakọta diski ahụ na-eji ihe mgbaka wiil agịga cycloid na-ebugharị mkpịsị mkpịsị ahụ, wee kwọọ ogwe aka na-akpali akpali ka ọ tụgharịa ma kpalie.Site na ntụgharị na-aga n'ihu na-akpali agụba na ogwe aka agwakọta, akụrụngwa na-agwakọta nke ọma.A na-ewepụ ihe ndị a gwakọtara ọnụ site na ntinye na ala.Disk ahụ na-anabata efere polypropylene ma ọ bụ ihe mkpuchi igwe anaghị agba nchara, nke na-adịghị mfe ịrapara ma dị mfe ma dị irè.

3. Roll Extrusion Granulator

A na-ebufe akụrụngwa agwakọta site na eriri belt gaa na diski diski, nke na-ezigara ihe ahụ n'otu n'otu na-ebuga rola anọ n'okpuru onye na-enye nri site na hopper.Igwe ahụ na-atụgharị ihe ahụ n'ime iberibe n'ime ụlọ gbajiri agbaji n'okpuru ihe mkpuchi ahụ site na ntụgharị na-atụgharị elu voltaji na-agbanwe agbanwe, wee kewaa ihe ndị a chọrọ ka mkpanaka anụ ọhịa wolf okpukpu abụọ na-atụgharị.A na-eji ihe ọhụrụ na-eguzogide corrosion, eyi na-eguzogide ọgwụ na mmetụta na-eguzogide ọgwụ alloy.

4. Rotary Drum Screene

A na-ebuga ụmụ irighiri ihe granulation kpụ ọkụ n'ọnụ gaa na nzacha rola site na ebufe belt, ụmụ irighiri ihe ndị na-adịghị mma na-esi na nnukwu ahụ pụta n'akụkụ site na oghere ihuenyo, wee bufee ya na diski diski maka granulation nke abụọ, a na-enye ụmụ irighiri ihe ruru eru site na ọnụ ala njedebe ma bufee ya na mpaghara emechara.

5. Igwe ngwungwu igwe eletrọnịkị

Site na hopper, a na-atụ ihe ndị tozuru etozu nke ọma, wee chịkọta ya site na igwe nkwakọ ngwaahịa akpaka.