Anyị nwere ahụmahụ zuru oke na ahịrị mmepụta fatịlaịza.Ọ bụghị nanị na anyị na-elekwasị anya na usoro ọ bụla njikọ na mmepụta usoro, kamakwa mgbe ịghọta usoro nkọwa nke ọ bụla dum mmepụta akara na were were nweta interlinking.Anyị na-enye ahaziri mmepụta ahịrị ngwọta dị ka n'ezie mkpa nke ndị ahịa.

Usoro mmepụta zuru oke bụ otu n'ime uru dị mkpa nke imekọ ihe ọnụ gị na Yuzheng Heavy Industries.Anyị na-enye usoro nhazi na imepụta usoro mmepụta nke ahịrị mmepụta nke drum granulation.

Fatịlaịza mgbagwoju anya bụ fatịlaịza ngwakọta nwere nitrogen, phosphorus na potassium, nke a na-agwakọta dị ka akụkụ ụfọdụ nke otu fatịlaịza si dị ma na-ejikọta ya site na mmeghachi omume kemịkal.Nri ọdịnaya bụ edo na urughuru size bụ otu.The compound fatịlaịza mmepụta akara nwere obosara adaptability ka granulation nke dị iche iche compound fatịlaịza akụrụngwa.

Ngwakọta fatịlaịza nwere njiri mara granulation otu, agba na-egbuke egbuke, ịdị mma kwụsiri ike, yana mgbasa dị mfe nke ihe ọkụkụ ga-etinye obi gị dum.Karịsịa, ọ dịtụ mma maka mkpụrụ na-eto fatịlaịza.Kwesịrị ekwesị maka ụdị ala na ọka wit niile, ọka, egusi na mkpụrụ osisi, ahụekere, akwụkwọ nri, agwa, ifuru, osisi mkpụrụ osisi na ihe ọkụkụ ndị ọzọ.Ọ dabara maka fatịlaịza isi, fatịlaịza, ịchụ fatịlaịza, fatịlaịza na ogbugba mmiri n'ubi.

Akụrụngwa maka mmepụta fatịlaịza na-agụnye urea, ammonium chloride, ammonium sulfate, mmiri mmiri amonia, ammonium monophosphate, diammonium phosphate, potassium chloride, potassium sulfate, gụnyere ụfọdụ ụrọ na ihe ndị ọzọ.A na-agbakwunye ihe organic dị iche iche dịka mkpa ala si dị:

1. Nri anụ: ọkụkọ, nsị ezì, nsị atụrụ, egwu ehi, nsị ịnyịnya, nri oke bekee, wdg.

2, mkpofu ụlọ ọrụ: mkpụrụ vaịn, mmanya slag, ihe fọdụrụ akpu, ihe fọdụrụ sugar, mkpofu biogas, ihe fọdụrụ ajị, wdg.

3. Ihe mkpofu ugbo: ahihia ihe ubi, ntụ ọka soybean, ntụ ọka owu, wdg.

4. Ihe mkpofu ụlọ: ihe mkpofu kichin

5, sludge: sludge mepere emepe, sludge osimiri, sludge nzacha, wdg.

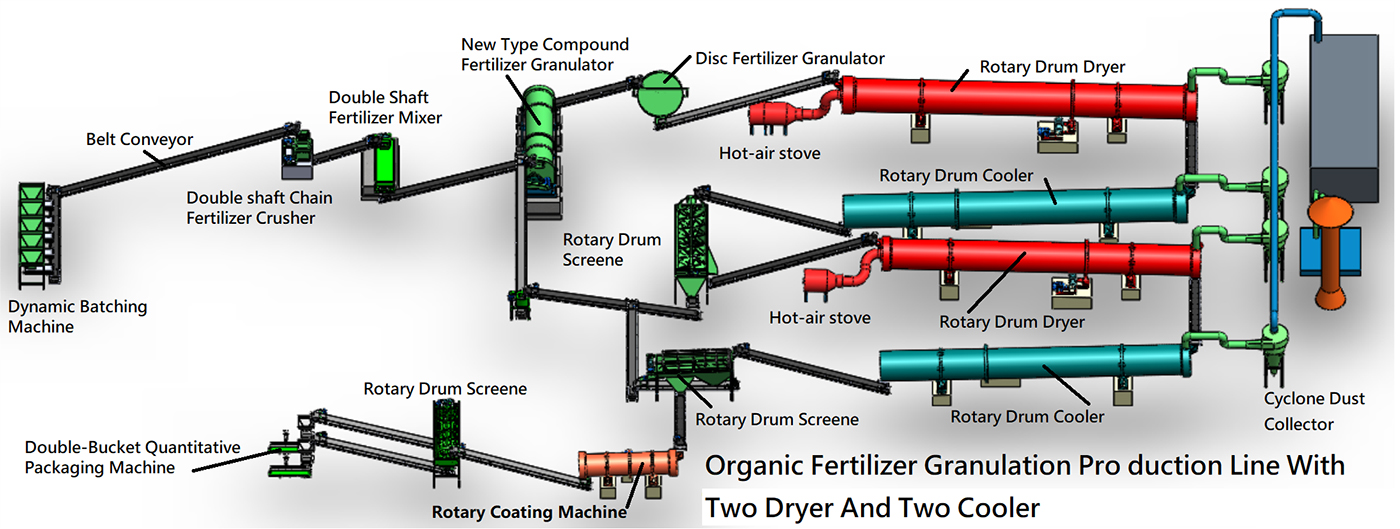

Ngwakọta fatịlaịza na-emepụta fatịlaịza nwere ihe na-agbanwe agbanwe, ihe na-eme ihe abụọ axis, granulator fatịlaịza ọhụrụ, ihe nhịahụ kwụ ọtọ, igwe na-ekpo ọkụ nke drum, igwe sieve drum, igwe mkpuchi, onye na-anakọta uzuzu, nkwakọ ngwaahịa akpaka. igwe na ngwa inyeaka ndị ọzọ.

Dị ka ọkachamara emeputa nke fatịlaịza mmepụta akara akụrụngwa, anyị na-enye ndị ahịa na mmepụta ahịrị na 10,000 tọn kwa afọ ka 200,000 tọn kwa afọ.

1. The granulation ọnụego dị elu dị ka 70% na elu drum granulation igwe.

2. Ihe ndị dị mkpa na-eji ihe ndị na-eyi ihe na-eguzogide ọgwụ na-eguzogide ọgwụ, na ngwá ọrụ ahụ nwere ogologo ndụ ọrụ.

3. The rotary drum granulator na-eji silicone ma ọ bụ igwe anaghị agba nchara, na ihe adịghị mfe ịrapara n'ime mgbidi nke igwe.

4. arụ ọrụ kwụsiri ike, mmezi dị mma, arụmọrụ dị elu na obere ike oriri.

5. Jiri eriri eriri eriri jikọọ eriri mmepụta niile iji nweta mmepụta na-aga n'ihu.

6. Jiri okpukpu abụọ nke ụlọ na-ewepụ uzuzu na-agwọ gas ọdụ maka nchebe gburugburu ebe obibi.

7. Nkewa nke ọrụ nke sieves abụọ na-eme ka o doo anya na nha nha ahụ bụ otu na àgwà ruru eru.

8. Ịgwakọta Uniform, ihicha, jụrụ oyi, mkpuchi na usoro ndị ọzọ na-eme ka ngwaahịa a rụchara dị elu na mma.

Usoro eruba nke ahịrị mmepụta fatịlaịza: akụrụngwa akụrụngwa → ngwakọta akụrụngwa → granulation → ihicha → jụrụ oyi → nyocha ngwaahịa emechara → obere iberibe plastik → mkpuchi → nkwakọ ngwaahịa ngwaahịa → nchekwa.Mara: ahịrị mmepụta a bụ naanị maka ntụnye aka.

Ngwa ngwa ngwa:

Dabere na ọchịchọ ahịa na nsonaazụ mkpebi ala mpaghara, urea, ammonium nitrate, ammonium chloride, ammonium thiophosphate, ammonium phosphate, diammonium phosphate, calcium siri ike, potassium chloride (potassium sulfate) na akụrụngwa ndị ọzọ na-ekesa n'otu akụkụ.A na-eji ihe mgbakwunye, ihe ndị na-achọpụta ihe, wdg. na-eji dị ka ihe eji eme ihe na akụkụ ụfọdụ site na eriri belt.Dị ka usoro nhazi ahụ si dị, a na-esi n'úkwù na-asọba ngwa ngwa ngwa ngwa, usoro a na-akpọ premixes.Ọ na-ahụ maka izi ezi nke nhazi ahụ ma nweta ihe oriri na-aga n'ihu nke ọma.

1. Ngwakọta:

A na-agwakọta ihe ndị a kwadebere n'ụzọ zuru ezu ma kpalie ya nke ọma, na-atọ ntọala maka fatịlaịza granular dị elu na nke dị elu.Enwere ike iji igwekota kwụ ọtọ ma ọ bụ igwekota diski maka ịgwakọta otu na ịkpali.

2. Ọkpụkpụ:

A na-ebufe ihe ahụ mgbe agwakọtara ya ma gwepịa ya nke ọma site na ebufe belt gaa na granulator fatịlaịza ọhụrụ.Site na ntụgharị na-aga n'ihu nke ịgbà ahụ, ihe ahụ na-eme ka ọkpụkpụ na-agagharị n'okporo ụzọ.N'okpuru nrụgide extrusion nke a na-emepụta, a na-ejikọta ihe ahụ n'ime obere akụkụ ma tinye ya na ntụ ntụ gbara ya gburugburu iji jiri nwayọọ nwayọọ mepụta ọdịdị okirikiri ruru eru.Granules.

3. granules akọrọ:

Ihe granulation chọrọ ka akpọnwụ tupu ya enwee ike iru ihe achọrọ nke ọdịnaya mmiri.Mgbe draya na-atụgharị, efere na-ebuli n'ime ya na-ebuli ma na-atụba ihe ndị na-akpụzi ahụ, nke mere na ihe ahụ dị na kọntaktị zuru oke na ikuku na-ekpo ọkụ iji wepụ mmiri mmiri na ya, iji nweta ihe mgbaru ọsọ nke ihicha edo.Ọ na-anabata usoro nhicha ikuku nke kwụụrụ onwe ya ka ọ na-ebunye gas na-ekpocha ọkụ ma chekwaa ike yana belata oriri.

4. Granule jụrụ:

Mgbe a kpochapụrụ ihe ndị ahụ, ọ dị mkpa ka ezipụ ha na ngwa nju oyi maka oyi.Eji eriri eriri jikọọ igwe nju oyi na igwe nkụ.Igwe jụrụ oyi nwere ike wepu uzuzu, melite arụmọrụ nju oyi na iji ume ọkụ na-ekpo ọkụ, na-ewepụkwa mmiri mmiri n'ime ahụ.

5. Nyocha:

Mgbe a na-eme ka ihe ndị ahụ dị mma, a na-ekpuchi ihe niile dị mma na nke buru ibu site na sieve roller.A na-akpali ngwaahịa ndị na-erughị eru nke a na-esi na eriri eriri na-ebuga na blender ma gbanye ya na akụrụngwa ọzọ.A ga-ebuga ngwaahịa emechara na igwe mkpuchi fatịlaịza.

6. Nri:

A na-ejikarị etinye ihe nkiri nchebe edo n'elu ihe ndị emechara nke ọma iji mee ka ndụ ndụ dị mma nke ọma dịkwuo mma ma mee ka ahụ dị nro.Mgbe mkpuchi gasịrị, ọ bụ njikọ ikpeazụ na usoro mmepụta dum - nkwakọ ngwaahịa.

7. Nkwakọ ngwaahịa:

Usoro a na-ewere igwe nkwakọ ngwaahịa akpaka.Igwe a na-eji igwe na-atụ ihe na-akpaghị aka, usoro ihe na-ebufe, igwe mkpuchi, wdg Ị nwekwara ike hazie hoppers dịka ihe ndị ahịa chọrọ.Ọ nwere ike na-aghọta na quantitative nkwakọ nke nnukwu ihe dị ka organic fatịlaịza na ngwakọta fatịlaịza.