Ngwa mmepụta fatịlaịza maka nri ezi

Ngwa mmepụta fatịlaịza maka nri ezì na-agụnye usoro na akụrụngwa ndị a:

1.Nchịkọta na nchekwa: A na-anakọta nri ezì ma chekwaa ya n'ebe a kara aka.

2.Drying: A na-akpọ nri ezì iji belata ọdịnaya mmiri ma kpochapụ ọrịa.Akụrụngwa ihicha nwere ike ịgụnye igwe nkụ rotary ma ọ bụ igwe nkụ.

3.Crushing: A na-echipịa nri ezì a mịrị amị iji belata nha nha maka nhazi ọzọ.Ngwa ịzọpịa nwere ike ịgụnye igwe nzọpịa ma ọ bụ igwe igwe hama.

4.Mixing: A na-agbakwunye ihe mgbakwunye dị iche iche, dị ka nitrogen, phosphorus, na potassium, na nri ezì a gbajiri agbaji iji mepụta fatịlaịza kwesịrị ekwesị.Ngwakọta agwakọta nwere ike ịgụnye igwekota kehoraizin ma ọ bụ igwekota kwụ ọtọ.

5.Granulation: A na-emepụta ngwakọta ahụ n'ime granules maka ịdị mfe nke njikwa na ngwa.Akụrụngwa granulation nwere ike ịgụnye granulator diski, granulator drum rotary, ma ọ bụ granulator pan.

6.Ihicha na ime ka obi dị jụụ: A na-akpọzi granules ọhụrụ a na-eme ka ọ dị jụụ ma mee ka ha sie ike ma gbochie nkwụsị.Akụrụngwa ihicha na jụrụ oyi nwere ike ịgụnye igwe nkụ nke rotary na igwe nju oyi.

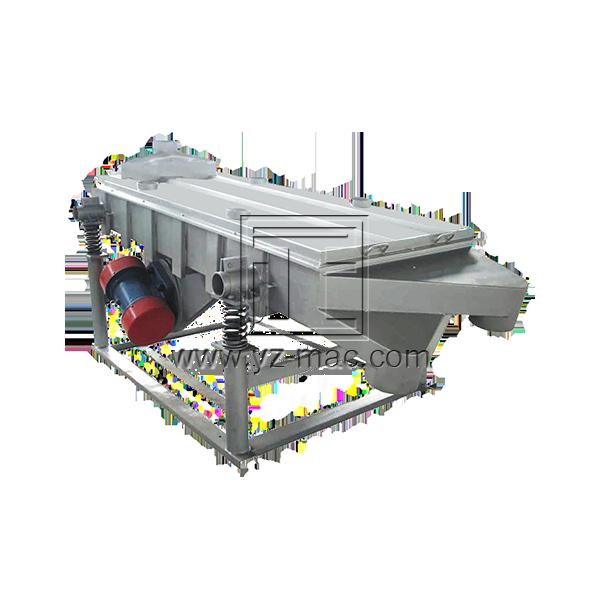

7.Screening: A na-ekpuchi fatịlaịza a gwụchara iji wepụ ihe ọ bụla buru ibu ma ọ bụ ihe na-erughị ala.Akụrụngwa nyocha nwere ike ịgụnye ihe nyocha rotary ma ọ bụ ihe nyocha nke na-ama jijiji.

8.Coating: Enwere ike itinye mkpuchi na granules iji chịkwaa ntọhapụ na-edozi ahụ ma melite ọdịdị ha.Ngwa mkpuchi nwere ike ịgụnye igwe mkpuchi rotary.

9.Packaging: Nzọụkwụ ikpeazụ bụ ịkwado fatịlaịza emechara n'ime akpa ma ọ bụ ihe ndị ọzọ maka nkesa na ire ere.Akụrụngwa nkwakọ ngwaahịa nwere ike ịgụnye igwe akpa ma ọ bụ igwe na-atụ ihe na ndochi.