Immalite nke Compound fatịlaịza Production Line

Ngwakọta fatịlaịza bụ fatịlaịza nke nwere nri abụọ ma ọ bụ atọ nke N, P;K. Ngwakọta fatịlaịza dị na ntụ ntụ ma ọ bụ ụdị granular.A na-ejikarị ya eme ihe dị ka akwa akwa, a pụkwara iji ya dị ka nri isi na nri mkpụrụ.Ngwakọta fatịlaịza nwere ihe ndị dị elu dị elu, ya mere ọ na-adị mfe soluble na mmiri, na-agbaze ngwa ngwa, na usoro mgbọrọgwụ na-etinye ya ngwa ngwa, ya mere a na-akpọ ya "fatịlaịza na-eme ngwa ngwa".Ọrụ ya bụ imezu ihe niile achọrọ na ịhazi nri dị iche iche nke ihe ọkụkụ chọrọ n'okpuru ọnọdụ dị iche iche.

A na-ejikarị ahịrị mmepụta fatịlaịza a na-emepụta granules fatịlaịza na-eji ihe NPK, GSSP, SSP, potassium sulphate granulated, sulfuric acid, ammonium nitrate, na ndị ọzọ.Ngwa ngwa fatịlaịza nwere uru nke ịgba ọsọ kwụsiri ike, ọnụego adịghị arụ ọrụ dị ala, obere mmezi na ọnụ ala dị ala.

Ejiri ngwa ọrụ dị elu na nke na-arụ ọrụ nke ọma, nke nwere ike ịrụpụta ihe dị ka tọn 50,000 nke fatịlaịza kwa afọ.Dị ka ezigbo mmepụta ikike chọrọ, anyị na-eme atụmatụ ma chepụta ahịrị mmepụta fatịlaịza nwere ikike dị iche iche kwa afọ nke 10,000 ~ 300,000 tọn.Ihe niile nke akụrụngwa bụ kọmpat, ezi uche, sayensị, arụ ọrụ kwụsiri ike, nchekwa ike, ọnụ ahịa mmezi dị ala, dị mfe iji rụọ ọrụ, bụ nhọrọ kacha mma maka ndị na-emepụta fatịlaịza.

Ọkara ngwakọta fatịlaịza mmepụta ahịrị usoro

Enwere ike kewaa ahịrị mmepụta ihe fatịlaịza n'ozuzu n'ime: akụrụngwa batching, ịgwakọta, nchikota, granulating, nyocha mbụ, ihicha granule na jụrụ oyi, nyocha nke abụọ, mkpuchi granule na nkwakọ ngwaahịa.

1. Raw material batching: dị ka ahịa chọrọ na mpaghara mkpebi mkpebi siri ike, akụrụngwa dị ka urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, arọ calcium, general calcium) na potassium chloride ( potassium sulfate) ga-ekenye n'otu akụkụ.A na-atụnye ihe mgbakwunye na ihe ndị a na-achọpụta site n'ọ̀tụ̀tụ̀ belt ma kwekọọ n'otu akụkụ.Dị ka usoro usoro ahụ si dị, a na-agwakọta ngwa ngwa niile site na igwekota.A na-akpọ usoro a premix.Ọ na-eme ka usoro nhazi ziri ezi ma na-enyere aka ịrụ ọrụ nke ọma na nke na-aga n'ihu.

2. Ịgwakọta: Gwakọta ihe ndị a kwadebere nke ọma ma kpalie ha nke ọma, nke na-atọ ntọala maka fatịlaịza granular dị mma na nke dị elu.Enwere ike iji igwekota kwụ ọtọ ma ọ bụ igwekota diski maka ọbụna ịgwakọta.

3. Na-etipịa: Iji gwepịa caking na ihe dị mkpa maka nhazi granulation na-esote.A na-ejikarị ihe nhịahụ eme ihe.

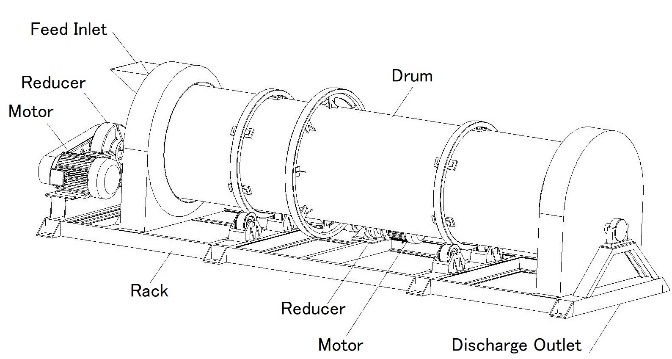

4. Granulating: A na-ebufe ihe ndị na-akpali akpali ma na-egweri na granulator site na eriri eriri maka granulating, nke bụ akụkụ bụ isi nke ahịrị mmepụta dum.Nhọrọ nke granulator dị ezigbo mkpa, anyị nwere diski granulator, rotary drum granulator, roller extrusion granulator ma ọ bụ ngwakọta fatịlaịza granulator maka nhọrọ.

5. Nleba anya nke mbụ: Were nyocha izizi maka granules, ma laghachi ndị na-erughị eru na ngwepịa maka nhazigharị.N'ozuzu, a na-eji igwe nyocha rotary.

6. ihicha: A na-ebufe granules ndị ruru eru mgbe nyocha nke mbụ site na eriri eriri na igwe na-ebugharị rotary maka ihicha iji belata mmiri nke granules emechara.Mgbe ihichachara, mmiri ọdịnaya nke granules ga-ebelata site na 20% -30% ruo 2% -5%.

7. Granules jụrụ oyi: Mgbe ihichachara, a ga-eziga granules na ngwa nju oyi maka ime ka ọ dị jụụ, nke ejikọrọ na ọkpọkọ site na eriri eriri.Igwe oyi ahụ nwere ike wepu uzuzu, melite arụmọrụ jụrụ oyi na oke ojiji okpomọkụ, ma wepụkwa mmiri dị na fatịlaịza.

8. Nyochaa nke abụọ: Mgbe ọ dị jụụ, a na-enyocha granules niile na-erughị eru site na igwe nyocha rotary wee bufee eriri eriri na igwekota wee gwakọta ya na ngwa ndị ọzọ maka nhazigharị.A ga-ebuga ngwaahịa ndị emechara na igwe mkpuchi fatịlaịza.

9. mkpuchi: A na-ejikarị kpuchie elu nke quasi-granules na ihe nkiri nchebe edo ka ọ gbasaa oge nchekwa nke ọma ma mee ka granules dị nro.Mgbe mkpuchi gasịrị, ebe a bịarutere usoro ikpeazụ - nkwakọ ngwaahịa.

10. Usoro nkwakọ ngwaahịa: A na-anakwere igwe nkwakọ ngwaahịa akpaaka na usoro a.Igwe a na-eji igwe na-atụnye akpaaka na ịkwakọba ihe, usoro nnyefe, igwe mkpuchi na ihe ndị ọzọ.Enwere ike ịhazi Hopper dịka ihe ndị ahịa chọrọ.A na-eji nchịkọta ọnụ ọgụgụ nke nnukwu ihe dị ka fatịlaịza organic na fatịlaịza ngwakọta eme ihe n'ọtụtụ ebe n'ime ụlọ ọrụ na ubi dị iche iche.

Nkà na ụzụ na atụmatụ nke ahịrị mmepụta fatịlaịza:

A na-ejikarị Rotary drum granulator na-emepụta teknụzụ fatịlaịza fatịlaịza dị elu, enwere ike iji diski na-abụghị steam granulator na mmepụta nke teknụzụ fatịlaịza dị elu, ọkara na nke dị ala, jikọtara ya na teknụzụ mgbochi-caking, nitrogen dị elu. teknụzụ na-emepụta fatịlaịza na ihe ndị ọzọ.Ahịrị mmepụta fatịlaịza anyị nwere njirimara ndị a:

1. Wide applicability nke akụrụngwa: compound fatịlaịza nwere ike na-emepụta dị iche iche formulations na n'ike-n'ike, na ọ dịkwa mma maka mmepụta nke organic na inorganic compound fatịlaịza.

2. Ọnụ ọgụgụ dị elu nke na-emepụta pellet na ọnụọgụ ndụ nke nje bacteria na-ahụ maka ndụ: nkà na ụzụ ọhụrụ nwere ike ime ka ọnụ ọgụgụ nke pellet ruru 90% ~ 95%, na obere okpomọkụ na ikuku ihicha nkà na ụzụ nwere ike ime ka ọnụọgụ ndụ nke nje bacteria na-adị ndụ. rute 90%.Ngwaahịa emechara dị mma na ọdịdị na nha nha, 90% nke bụ granules nwere nha nke 2 ~ 4mm.

3. Mgbanwe usoro eruba: The usoro eruba nke compound fatịlaịza mmepụta akara nwere ike gbanwee dị ka n'ezie akụrụngwa, usoro na saịtị, na ahaziri usoro eruba nwekwara ike e mere dị ka n'ezie mkpa.

4. Stable nutrient ruru nke okokụre ngwaahịa: site akpaka metering nke Efrata, ezi metering nile di iche iche nke siri ike, mmiri mmiri na ndị ọzọ na akụrụngwa, fọrọ nke nta nọgidere na-enwe kwụsie ike na irè niile nri na dum usoro.

COmpound Fertiliser Production LineNgwa

1.Sulfur mkpuchi urea mmepụta usoro.

2.Different ụdị organic na inorganic fatịlaịza usoro.

3.Acid compound fatịlaịza granulation usoro.

4.Powdery ulo oru mkpofu inorganic fatịlaịza usoro.

5.Large urughuru urea mmepụta usoro.

6.Seedling Substrate mmepụta usoro.

Oge nzipu: Sep-27-2020