Ngwa mmepụta fatịlaịza na-adịghị ihicha extrusion

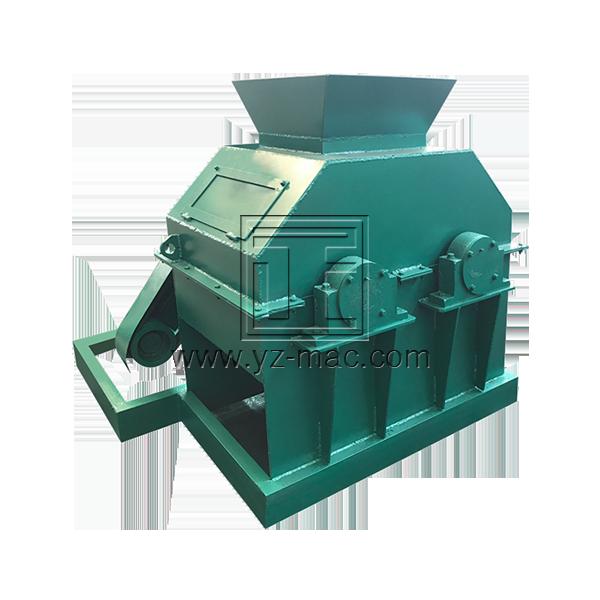

A na-eji akụrụngwa na-emepụta fatịlaịza na-adịghị akpọnwụ akpọnwụ iji mepụta fatịlaịza ngwakọta site na usoro a na-akpọ extrusion.Enwere ike iji igwe na ngwaọrụ dị iche iche mejupụtara akụrụngwa a, dabere n'ụdị nrụpụta na ọkwa nke akpaaka chọrọ.Nke a bụ ụfọdụ akụrụngwa bụ isi enwere ike iji mepụta fatịlaịza ogige extrusion na-adịghị akpọnwụ:

1.Crushing Machine: A na-eji igwe a na-akụpịa ihe ndị na-emepụta ihe n'ime ihe ndị dị nta, nke nwere ike inye aka mee ka mma nke fatịlaịza gwụchara.

2.Mixing Machine: Mgbe a na-egwepịa ihe ndị ahụ, a na-ejikọta ha ọnụ iji mepụta ngwakọta fatịlaịza kwesịrị ekwesị.Igwe na-agwakọta ihe nwere ike inye aka hụ na agwakọta ihe ndị ahụ nke ọma.

3.Extrusion Machine: A na-eji igwe a na-emepụta ihe ndị a gwakọtara n'ime pellets cylindrical ma ọ bụ spherical, nke a na-akpọnwụ ma kpuchie ya na mkpuchi nchebe.Usoro extrusion nwere ike inye aka melite njupụta na ike nke fatịlaịza, nke nwere ike imeziwanye irè ya.

4.Drying Machine: Ozugbo a na-emepụta pellets extruded, a pụrụ iji igwe ihicha wepụ mmiri na-ekpo ọkụ ma mepụta ngwaahịa kwụsiri ike.

5.Coating Machine: Enwere ike iji igwe a na-ekpuchi pellet fatịlaịza a rụchara na ihe nchebe dị mkpa, nke nwere ike inye aka gbochie mmiri mmiri ma melite absorption nke nri.

6.Packing Machine: Enwere ike iji igwe na-akwakọba ngwongwo fatịlaịza a rụchara n'ime akpa ma ọ bụ akpa, nke na-eme ka ọ dị mfe ibufe na ire ere.

Ọ dị mkpa iburu n'obi na igwe ndị a bụ naanị ihe atụ nke akụrụngwa enwere ike iji mepụta fatịlaịza ihe na-adịghị akpọnwụ akpọnwụ.Ngwá ọrụ a kapịrị ọnụ dị mkpa ga-adabere n'ọtụtụ mmepụta na ihe ndị dị mkpa nke usoro mmepụta ihe.Na mgbakwunye, nhazi nke fatịlaịza nwekwara ike ịchọ akụrụngwa pụrụ iche maka ịgwakọta na njikwa akụrụngwa.