Otu n'ime uru ndị bụ isi na-arụ ọrụ na Yi Zheng bụ ihe ọmụma usoro anyị zuru ezu;anyị abụghị naanị ndị ọkachamara n'otu akụkụ nke usoro a, kama nke ahụ, akụkụ ọ bụla.Nke a na-enye anyị ohere ịnye ndị ahịa anyị echiche pụrụ iche banyere otu akụkụ ọ bụla nke usoro ga-esi rụọ ọrụ ọnụ n'ozuzu ya.

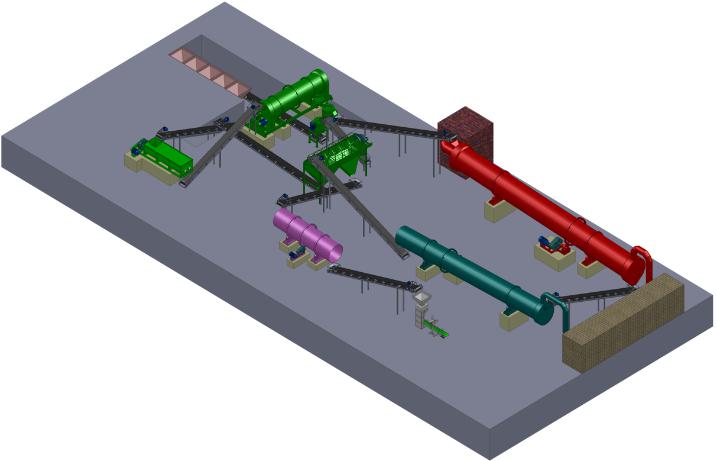

Anyị nwere ike na-enye usoro imewe na ọkọnọ nke a rotary drum granulation mmepụta akara.

Ejiri ahịrị mmepụta nke Rotary Drum Granulation nwere igwe static batching, igwekota okpukpu abụọ, rotary drum granulator, chain crusher, igwe nkụ rotary & ngwa nju oyi, igwe na-enyocha drum rotary na akụrụngwa fatịlaịza ndị ọzọ.Ihe a na-emepụta kwa afọ nwere ike ịbụ tọn 30,000.Dị ka ọkachamara fatịlaịza mmepụta ahịrị emeputa, anyị na-enye ndị ahịa ndị ọzọ granulation ahịrị dị iche iche mmepụta ikike, dị ka 20,000 T / Y, 50,000T / Y, na 100,000T / Y, wdg.

Uru:

1. Nakweere elu rotary drum granulator, ọnụ ọgụgụ granulation nwere ike iru 70%.

2. Akụkụ ndị dị mkpa na-eji ihe ndị na-eyi uwe na-eguzogide ọgwụ na corrosion, ngwá ọrụ nwere ogologo ndụ ọrụ.

3. Nabata efere plastik ma ọ bụ igwe anaghị agba nchara, ihe adịghị mfe ịrapara na mgbidi dị n'ime igwe.

4. Arụ ọrụ kwụsiri ike, mmezi dị mfe, arụmọrụ dị elu, obere ike oriri.

5. Nabata ebufe eriri iji jikọọ ahịrị dum, na-achọpụta mmepụta na-aga n'ihu.

6. Nabata ụlọ abụọ na-edozi uzuzu ka ị na-emeso gas ọdụ, enyi na gburugburu ebe obibi.

7. ugboro abụọ nke usoro nyocha hụ na granules ruru eru na nha nha.

8. Ngwakọta mgbe niile, ihicha, dị jụụ, na mkpuchi, ngwaahịa a gwụchara nwere mma dị elu.

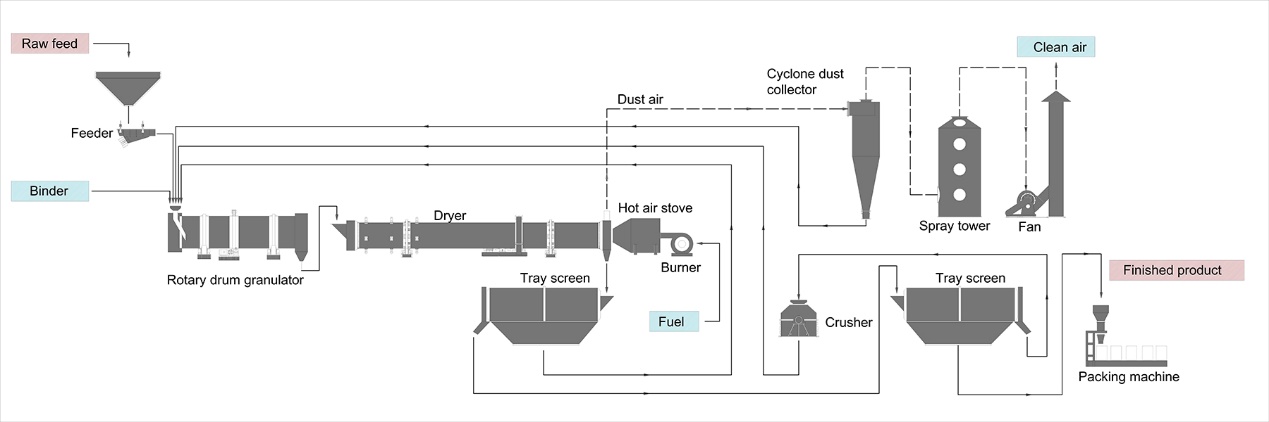

Usoro eruba:

Raw material batching (igwe batching static) → Ngwakọta (igwe igwe abụọ abụọ) → granulating (rotary drum granulator) → Drying (rotary drum dryer) → Ntu oyi (igwe nju oyi rotary) granules-etipịa ( vetikal fatịlaịza yinye crusher) → mkpuchi (igwe mkpuchi rotary drum) → Mkpokọta ngwaahịa emechara (akpaaka quantitative packr) → Nchekwa (na-echekwa n'ebe dị jụụ na nkụ)

IHE:Ahịrị mmepụta a bụ naanị maka ntụnye aka gị.

1.Raw ihe batching

Dabere n'ọchịchọ ahịa na nsonaazụ mkpebi ala mpaghara, a ga-ekenye akụrụngwa dị ka urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, calcium siri ike, calcium izugbe) na potassium chloride (potassium sulphate) n'ókè ụfọdụ.A na-atụnye ihe mgbakwunye na ihe ndị a na-achọpụta site n'ọ̀tụ̀tụ̀ belt ma kwekọọ n'otu akụkụ.Dị ka usoro usoro si dị, ihe niile na-emepụta ihe na-ejikọta ya na igwekota.A na-akpọ usoro a premix.Ọ na-eme ka usoro nhazi ziri ezi ma na-enyere aka ịrụ ọrụ nke ọma na nke na-aga n'ihu.

2.Na-agwakọta

Gwakọta ihe ndị a kwadebere nke ọma ma kpalie ha nke ọma, nke na-atọ ntọala maka fatịlaịza granular dị mma na nke dị elu.Enwere ike iji igwekota kwụ ọtọ ma ọ bụ igwekota diski maka ọbụna ịgwakọta.

3.Materials Granulating

Mgbe a gwepịasịrị ya, a na-ebufe ihe n'ime granulator rotary site na ebufe eriri.Site n'ịgbagharị ụda mgbe niile, ihe ndị ahụ na-etolite akwa akwa, ma na-aga n'ụzọ ụfọdụ.N'okpuru ike extrusion nke a na-emepụta, ihe ndị ahụ na-agbakọta n'ime obere ihe, nke na-aghọ isi, na-ejikọta ntụ ntụ na gburugburu iji mepụta granules zuru oke.

4.Fertilizer ihicha

A ga-akpọnwụ ihe mgbe granulating wee ruo ọkọlọtọ ọdịnaya mmiri.Mgbe igwe nkụ na-agbagharị, usoro nke nku dị n'ime ga-ebuli ihe ahụ site n'itinye mgbidi dị n'ime nke nkụ.Mgbe ihe ahụ ruru ogo ụfọdụ iji tụgharịa ntù azụ azụ, ọ ga-adaghachi azụ na ala nke nkụ, wee gafee mmiri ọkụ na-ekpo ọkụ ka ọ na-ada.Independent ikuku ịkpọasị usoro, centralize mkpofu mkpofu na-arụpụta ike na-eri na-azọpụta.

5.Fertilizer jụrụ oyi

Igwe nju oyi rotary na-ewepụ mmiri fatịlaịza ma wedata ọnọdụ okpomọkụ, nke ejiri igwe na-ehicha rotary eme ihe na fatịlaịza organic na mmepụta fatịlaịza in-organic, nke na-abawanye ngwa ngwa jụrụ oyi, na-ebelata oke ọrụ.A pụkwara iji igwe nju oyi rotary mee ka ọ dị jụụ na ihe ndị ọzọ nwere ntụ ntụ & granular.

6.Fertilizer screening: Mgbe emechara ka ọ dị jụụ, a na-ekpuchi granules niile na-erughị eru site na igwe nyocha rotary ma bufee eriri eriri na igwekota wee gwakọta ya na ngwa ndị ọzọ maka nhazigharị.A ga-ebuga ngwaahịa ndị emechara na igwe mkpuchi fatịlaịza.

7. mkpuchi: A na-ejikarị kpuchie elu nke quasi-granules na ihe nkiri nchebe edo ka ọ gbasaa oge nchekwa nke ọma ma mee ka granules dị nro.Mgbe mkpuchi, ebe a bịarutere usoro ikpeazụ - nkwakọ ngwaahịa.

8. Usoro nkwakọ ngwaahịa: A na-anakwere igwe nkwakọ ngwaahịa akpaaka na usoro a.Igwe a na-eji igwe na-atụnye akpaaka na ịkwakọ ngwaahịa, sistemu mbufe, igwe mkpuchi na ihe ndị ọzọ.Enwere ike ịhazi Hopper dịka ihe ndị ahịa chọrọ.A na-eji nchịkọta ọnụ ọgụgụ nke nnukwu ihe dị ka fatịlaịza organic na fatịlaịza ngwakọta eme ihe n'ọtụtụ ebe n'ime ụlọ ọrụ na ubi dị iche iche.

Oge nzipu: Sep-27-2020